Who we are

Welcome to Eco Delight Coffee

We have a wide collection of single origin coffee that comes from unique farms from around the world, including Ethiopia, Mexico, Costa Rica, El Salvador, Guatemala, Colombia and many others. We also have a rich set of coffee blends with a broad selection of flavors, textures, and aromas, whether you want an Espresso Blend or a Premium Dark Roast or a Premium Medium Roast Blend.

Eco Delight Coffee, LLC provides specialty roasted coffee produced in the western mountains of El Salvador known as Apaneca Ilamatepeq mountain range, Cordillera Central in Costa Rica and the Highlands of Mataquescuintla region in Guatemala. The farms where it is produced are located 4,500 feet above sea level.

Coffee cherries are selectively picked from the coffee trees and after harvesting they go through a wet process in the coffee mills which end product is coffee in parchment (pergamino) state.

Green coffee is imported and Roasting/Grinding and packaging is then made in our Roasting Plant in Elk Grove, CA

Sorting, grading and final inspection are done carefully by mechanical, electronic and manual operations.

Coffee it is

a way

of life

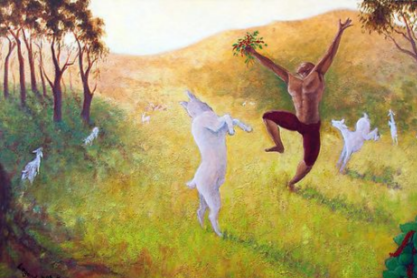

History

Our plants are grown at an optimal altitude of 1,800 to 2,200 meters above sea level, protected and nurtured under the shade of arboles de Grevillea, Kuje and others native to the highlands.

From our trees to your cup

Always fresh roast

Mission

Coffee is not just a hobby or a career, it is a way of life.

A lifetime of dedication and hard work has made that dream a reality. Five generations of coffee farmers lovingly and artfully tending their craft has evolved into an established business founded in integrity and sustainable craftsmanship.

As our business expands ECO DELIGHT feels driven to give back to the community that has provided the nurturing environment in which our business has been allowed to prosper. The farms from where we source our coffees provide employment opportunities for local residents and ensures fair and equal treatment of all collaborators and partners.

Values

We strive to give back to our community by creating job opportunities and ensuring the fair treatment of our partners and collaborators. Our vision has always been to improve the quality of life in surrounding communities while still caring for people locally and nurturing their lifestyle.

When it comes to improving a community’s quality of life, we recognize the importance of dental care. Dental care for children specifically can be preventative and caters to forming healthy habits that can carry on throughout their adult lives. Finca Santa Marta in the Highlands of Mataquescuintla Guatemala have created the organization Papa-moms it helps to bring a smile to a child by giving bicycles, doing activities and also provide dental cleaning once a year helping 100 children free of charge.

Our Blog

Recent Posts

Blog

Coffee Culture Around the World

2022

Coffee: A Healthy Outlier

2022